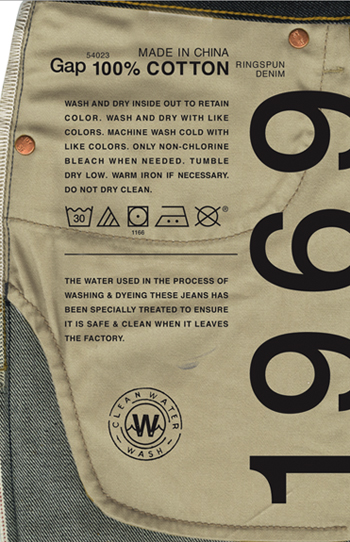

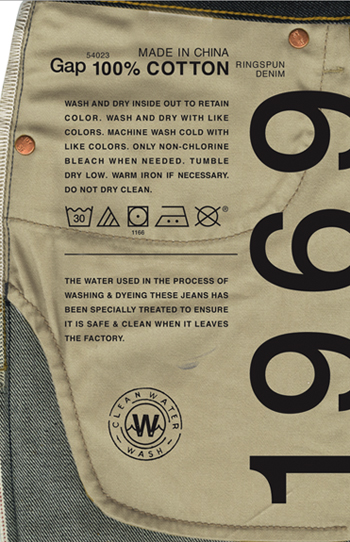

Gap Inc.’s Clean Water Program, established in 2004 to monitor water contamination, has now grown into a system that advertises zero waste from the factory. Inside the pocket of each pair of 1969 jeans you will find this statement:

“The water used in the process of washing & dying these jeans has been specially treated to ensure it is safe & clean when it leaves the factory.”

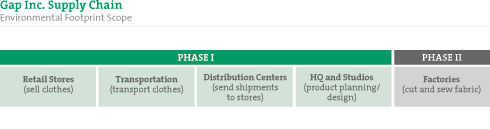

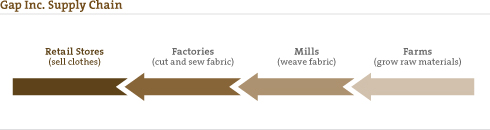

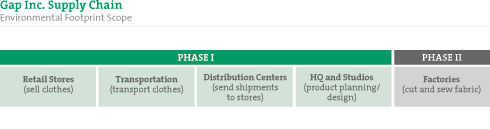

Here’s a closer look at how Gap Inc. breaks down its environmental footprint:

“The first phase of our environmental footprint assessment focuses on regions and facilities where we control operations and can make changes most easily. It includes our 11 headquarters (HQ) buildings, five design studios, seven distribution center campuses, and more than 2,800 stores in our North American fleet. Scheduled to be completed in 2009, this first phase will examine energy, water usage, effluents and waste (including wastewater, solid waste and hazardous waste).

The second phase of our assessment will focus further into our supply chain, where we have less direct influence but greater opportunity for impact. We expect to begin the second phase to begin in early 2010”

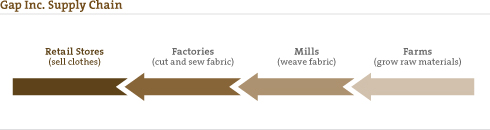

Unfortunately, the company does not appear, as of yet, to have goaled itself to take on the materials end of its supply chain. This is an oversight in responsible water-use, considering that 1kg of cotton requires 8000 litres of water. Not only does the materials end of the spectrum use a lot of water, but conventional cotton, with its heavy use of chemicals, results in dirty effluents.

On the Raw Materials end of the spectrum, low-water use cotton may be one option the company will be investigate in the future. Low-water use cotton is often rain-fed. Rain-fed cotton, however, risks the outcome of having a lower quality to it due to irregular water patterns (Fletcher). It will be interesting to see how the company tackles this phase of the lifecycle in the years ahead.

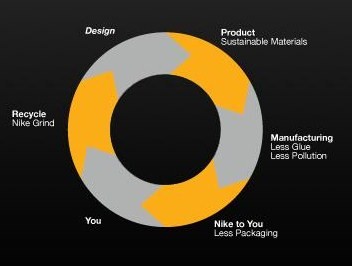

Lifecycle analysis should follow the impact of a garment at every stage: material, production, transportation, use, and disposal. One look at Gap Inc.’s supply chain and it becomes clear that the consumer is not considered in the environmental impact assessments. This is another oversight in the clean water program. Using the example of a simple T-shirt, Kate Fletcher states that consumer use

“has the highest impact and the effect of reducing the energy used in washing, drying and ironing […] dwarfs the possible effects of changing production methods.” (Fletcher)

This suggests that no matter what changes a company makes to clean-up water on the production side, heavy water use and dirty effluence on the consumer end may render such changes minimal when considered against the entire lifecycle of a garment.

One way the company could reduce both water use and contamination immediately is to start promoting responsible laundry habits, and engage consumers in the process. This could be as simple as creating a user friendly online site recommending best practices for each style of jean. This would involve simply directing customers to site for information and instructions.

In the future, why not add some responsible water care labels to each garment tag (a responsible extension off the already present ‘how to care for this garment’ instructions). For example, recommended laundry detergents, how much soap to use, and instructions on ways to avoid the dryer. (A common complaint about jeans that have been left to hang dry is that they wind up feeling stiff. Simple tip to avoid this is to air dry first, and then, if you have to, pop them in the dryer to soften them up for a few minutes before you wear them).

Of course there may be no real way of tracking consumer progress on the user end, but that’s no reason not to get behind consumer education when it comes to water consumption and the laundry machine.

Taken further, each Gap Inc. store would be able to provide consumers with the correct information on laundry detergents that are appropriate for the local water system in that particular area. Gap Inc. certainly has the resources to implement a program like this. Whether or not consumers will follow recommendations, is another story all together! Imagine the possibilities for a program like that.

Regardless of any oversights in the program, kudos to Gap Inc. not only for taking on this initiative, but for effectively implementing the goals it set out to achieve. This program will no doubt inspire competitors to think about water effluents and waste in their own supply chain.

Source: GreenBiz and Gap Inc.

Work Cited: Fletcher, Kate. Sustainable Fashion and Textiles: Design Journeys. London: Earthscan, 2008.