This post was written by Charlie Ross, Founder of Offset Warehouse and tells the story of one woman’s determination and drive for change. VOICES // a feature space on SA where community members are invited to share their journey in responsible design. What’s your story?

The first time ethical design came onto my radar was whilst I was studying for my BA in Fashion and it immediately struck a chord. Inspired by a friend to find out more about the social and environmental horrors underlying much of the fashion industry, I made an early decision to do everything I could to avoid contributing to it myself, with my own designs.

Having made the decision to ensure that everything I produced was as ethical as possible, I quickly discovered first hand how problematic this can be. I was desperate to ensure that my graduate collection was both environmentally and socially responsible, but I soon found that trying to find ethical suiting fabric light enough, let alone affordable, was impossible. Even hours of pleading with suppliers for sponsorship was to no avail (which, incidentally, is why I’m so keen to begin our sponsorship scheme, and have started a mailing list for all those interested!).

The closest I came to fulfilling my ambition of being truly ethical, was when I was given an opportunity to work with Reiko Sudo, founder of Nuno in Japan. She supplied me with recycled polyester for my shirts, and a recycled content fabric that could be manipulated with heat. The collaboration also came with a free ticket to Tokyo, so I attended the opening night of the exhibition where all the pieces were on display. The whole experience was inspirational and made me realise that my dream of a world of ethical fashion could become a reality.

The second part of my studies was a Masters in menswear design at the Royal College of Art. As wonderful as the opportunity was (and we all know how many famous designers started their careers there) I found myself constantly swimming against a strong current of professors and peers who didn’t agree with or understand my “green” thinking. It certainly didn’t correspond to their idea of “fashion”, but undeterred, I set to work creating a collection that would challenge their preconceptions: I would create a collection that was ethical and beautiful and fashion forward. And according to most, I succeeded.

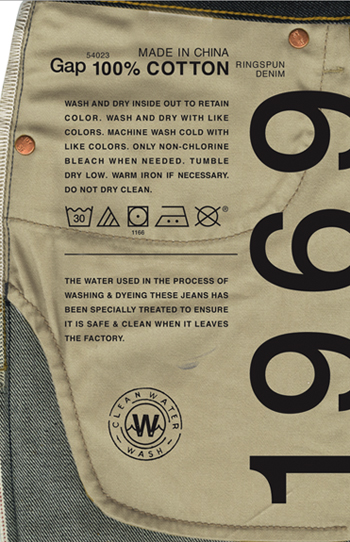

But my commitment to being ethical meant I doubled my workload. As most of the fabrics I chose were organic, and therefore only came in neutral tones, I spent hours dyeing them to match my colourways, whilst at the same time ensuring I had used the minimum quantities I needed, to limit the amount that would be put back into the “cycle”. I also ended up spending hours sifting through recycle banks to reclaim textiles – not to mention, the weeks of research it took to source the fabrics and services I needed. I had to find leathers that were by-products and vegetan, spray paint old tarpaulins to make into jackets, source vintage buttons and pieces I could use for clasps … and all this before I even started the pattern cutting!

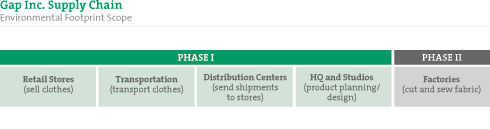

I realised very quickly that there needed to be a central source to go to for materials and information, if there was any chance of convincing those less committed than myself to take the ethical route in fashion. Yes, there were plenty of forums, but no solid solutions.

So, when I graduated from the RCA, I set about finding solutions to all the problems I had been faced with and Offset Warehouse was born. My idea was to make a wide range of ethical textiles available to buy in one place and also to offer the resources needed for research, as well as access to the ethical services and businesses needed to be able to manipulate the textiles – ethical dye labs, embroiderers, fair trade manufacturers, laser cutters, pattern cutters… you name it!

And of course, as proof that ethical fashion can be fashion forward and affordable, I also decided to include a boutique. It’s also proving a great solution for ethical students who want to sell their graduate collections!

I had a few struggles initially. Funding, of course, was a particular concern, but I finally decided that given the global nature of both my suppliers and potential users of the service, the most sensible place to set up the business was online. So that’s what I did and in turn, lowered the overheads of the business considerably.

Has it been an easy road? No, by no means. Surprisingly perhaps, in this day and age, I have found being a woman and only 26 has caused problems. It probably doesn’t help that I look younger than I am, but it makes me mad when I am patronised by individuals who assume that I am naive about the business. More fool them! Attending the RCA allowed me experiences far beyond those one might expect of someone of my age. I’ve had exposure working alongside and pitching to companies including Umbro, Brioni, Thierry Mugler, Zandra Rhodes and Vogue. Not to mention one to ones with the head designers of Versace, Givenchy and Valentino, and styling the rather difficult, Jonny Borrell (Razorlight) amongst other musical talents. Of course, it’s also part of my nature – I approach life with not just a “can do” attitude, but an “I can do it all” attitude. Since I launched Offset Warehouse, I’ve become my own buyer, a journalist, a web designer and developer, law copyrighter, marketeer, PR person (including making my own promotional videos), and SEO writer… it’s amazing the things you can learn from a few books, free workshops and youtube!

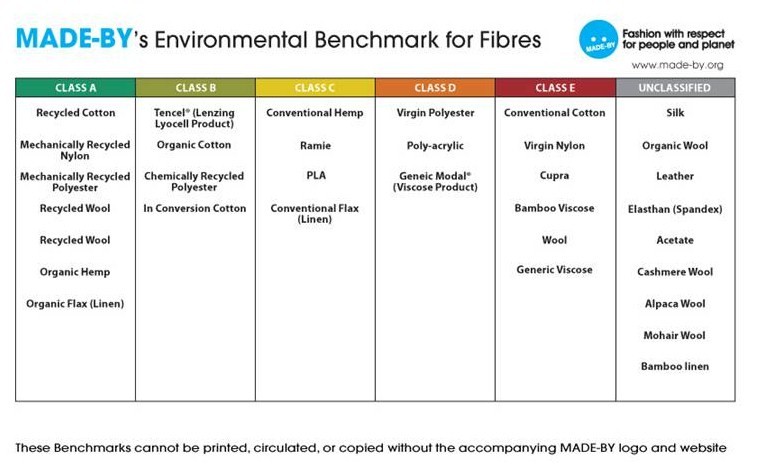

But this immensely steep learning curve shouldn’t have been necessary – I’m a great believer in passing on knowledge, which is why Offset Warehouse promotes learning and presents its own lectures and workshops. Knowledge is power, and understanding all aspects of being ethical – from the market, to what makes a fibre ethical, is, in my opinion, key to being a successful ethical designer. Passing on knowledge is central to our ethos, and we don’t just lecture about ethical issues, but also present workshops that will help designers further their careers – we review lots of CVs and portfolios of designers who want to be part of the Ethical Directory, and you wouldn’t believe how many applications could be improved with simple tricks!

Since our launch, we’ve had a huge response. It’s clear that we’re filling a gap in the market.

One unexpected development has been the demand for Offset Warehouse to provide consultancy. In response to the many requests we have had, I decided to establish a pool of consultants, all experts in their fields, who we can call upon to provide support to our clients. Ranging from referring a fair trade manufacturer (which we don’t charge for), to developing a range of ethical accessories. It’s been a fantastic addition to the business – and has left me wondering where we might go next… watch this space!

So here we are. Looking back, we have come farther than I could have dreamed at this point. It has not been an easy ride by any means and, looking forward, there is a long way to go for the industry to truly make a difference to the way it operates and the way it is perceived. I personally am very proud of how far we have come but Offset Warehouse still has much to do and I suspect the challenges will be different but no less demanding. Bring it on!